Operating Instruction

Operating Instruction

Maintenance guides

1) To clean the sprayer: Fill sprayer tank with clean water and bring the sprayer under pressure by pumping handle for several strokes,then squeezing the trigger to allow the clean water to flow into spraying lance and nozzle in order to clean the mechanism portion and nozzle.

2) To clean the nozzle (op.1) : Remove the nozzle cap (op.1) for cleaning. Repalce the cap after cleaning.

3) To clean teh filter(op.3) : Remove the filter from Auto Release(10).Replace the filter after cleaning.

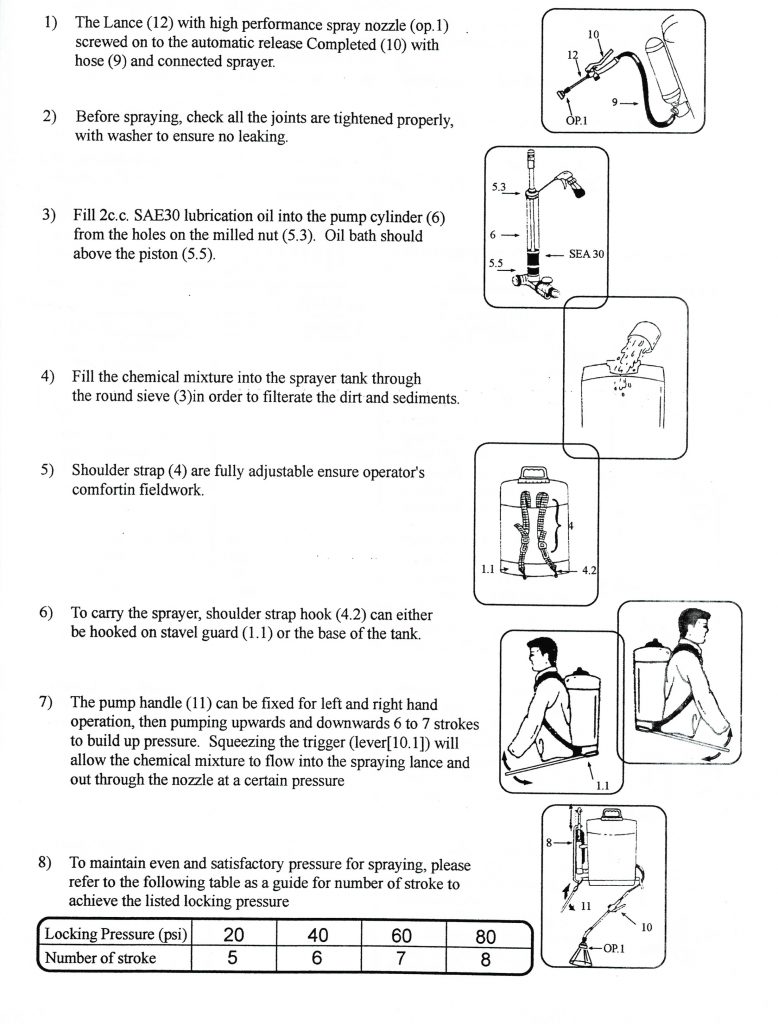

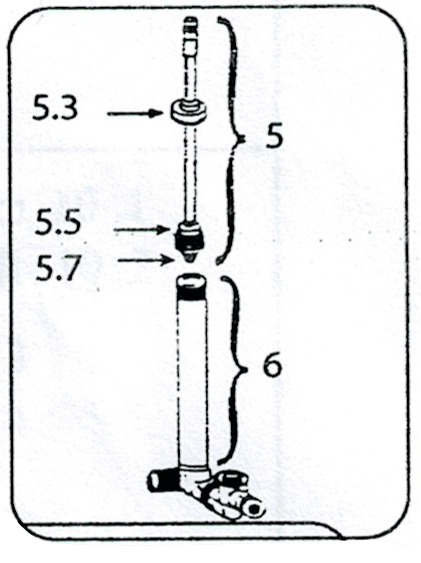

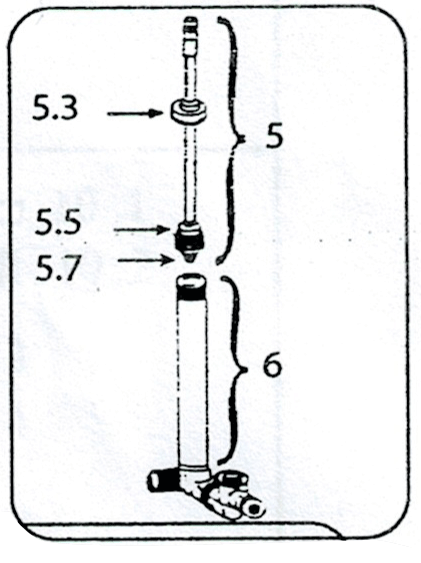

4) To clean the value of pump cylinder (6) : Unscrewing the air cylinder (8),take out the brass ball and replace them after washing and cleaning. Then fill 2c.c. SAE 30 lubricating oil into the pump cylinder(6)

5) All the joiners mst be tightened properly with washer.

Maintenance guides

1) To clean the sprayer: Fill sprayer tank with clean water and bring the sprayer under pressure by pumping handle for several strokes,then squeezing the trigger to allow the clean water to flow into spraying lance and nozzle in order to clean the mechanism portion and nozzle.

2) To clean the nozzle (op.1) : Remove the nozzle cap (op.1) for cleaning. Repalce the cap after cleaning.

3) To clean teh filter(op.3) : Remove the filter from Auto Release(10).Replace the filter after cleaning.

4) To clean the value of pump cylinder (6) : Unscrewing the air cylinder (8),take out the brass ball and replace them after washing and cleaning. Then fill 2c.c. SAE 30 lubricating oil into the pump cylinder(6)

5) All the joiners mst be tightened properly with washer.

It is very Important

Must clean the nozzle cap and filter(OP.3), properly after using the sprayer.

Problem & Remedies

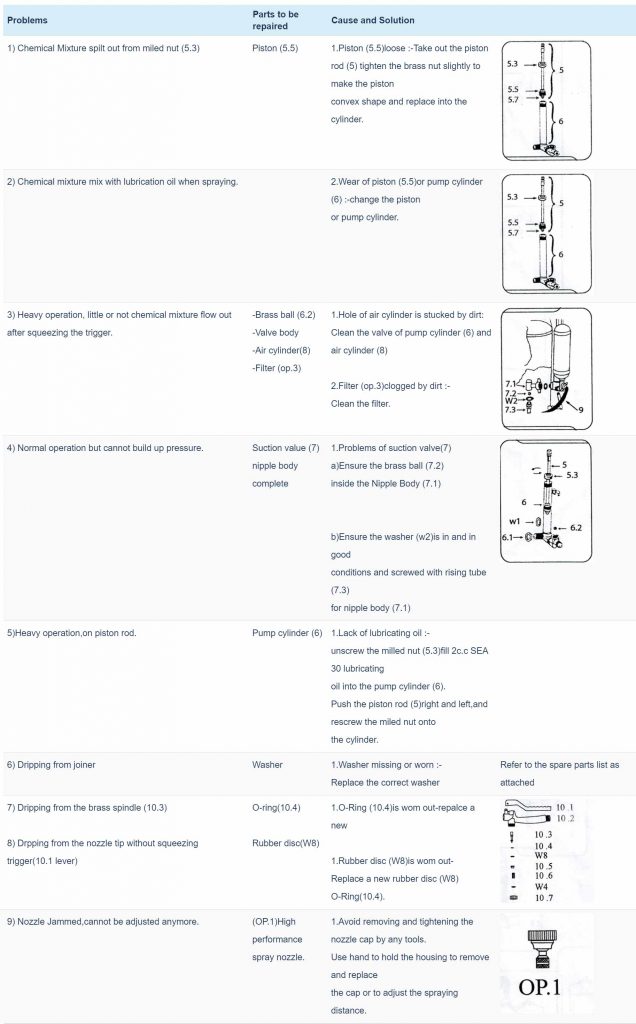

| Problems | Parts to be repaired | Cause and Solution | |

|---|---|---|---|

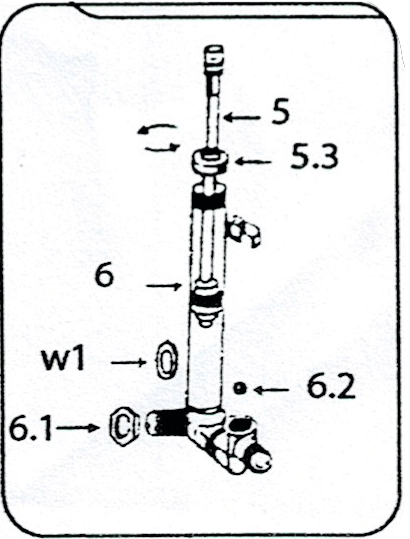

| 1) Chemical Mixture spilt out from miled nut (5.3) | Piston (5.5) | 1.Piston (5.5)loose :-Take out the piston rod (5) tighten the brass nut slightly to make the piston convex shape and replace into the cylinder. |  |

| 2) Chemical mixture mix with lubrication oil when spraying. | 2.Wear of piston (5.5)or pump cylinder (6) :-change the piston or pump cylinder. |  |

|

| 3) Heavy operation, little or not chemical mixture flow out after squeezing the trigger. | -Brass ball (6.2) -Valve body -Air cylinder(8) -Filter (op.3) | 1.Hole of air cylinder is stucked by dirt: Clean the valve of pump cylinder (6) and air cylinder (8) 2.Filter (op.3)clogged by dirt :- Clean the filter. |  |

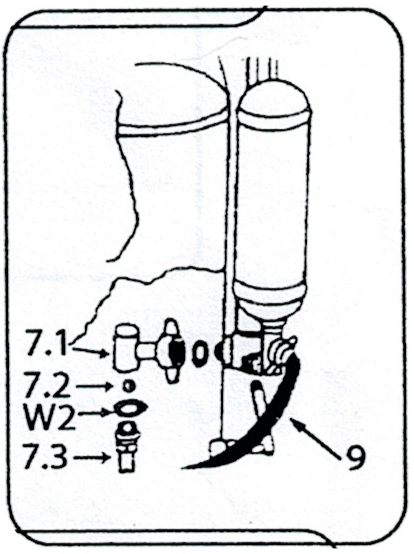

| 4) Normal operation but cannot build up pressure. | Suction value (7) nipple body complete | 1.Problems of suction valve(7) a)Ensure the brass ball (7.2) inside the Nipple Body (7.1) b)Ensure the washer (w2)is in and in good conditions and screwed with rising tube (7.3) for nipple body (7.1) |  |

| 5)Heavy operation,on piston rod. | Pump cylinder (6) | 1.Lack of lubricating oil :- unscrew the milled nut (5.3)fill 2c.c SEA 30 lubricating oil into the pump cylinder (6). Push the piston rod (5)right and left,and rescrew the miled nut onto the cylinder. | |

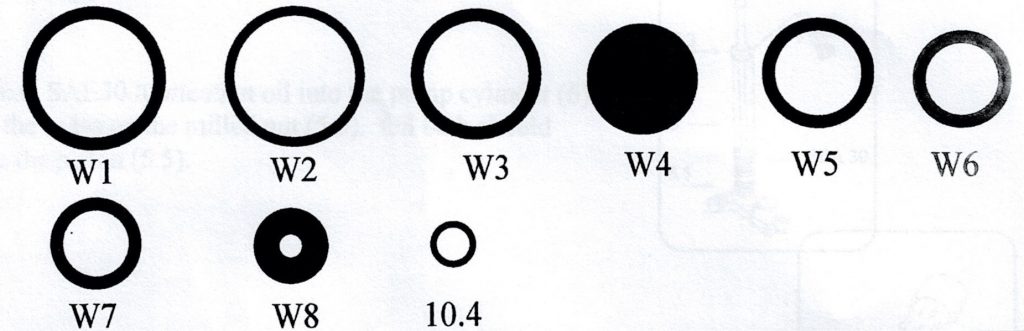

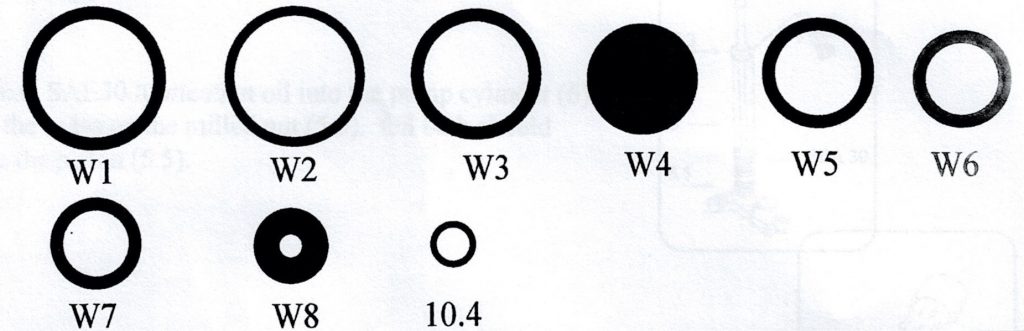

| 6) Dripping from joiner | Washer | 1.Washer missing or worn :- Replace the correct washer | Refer to the spare parts list as attached |

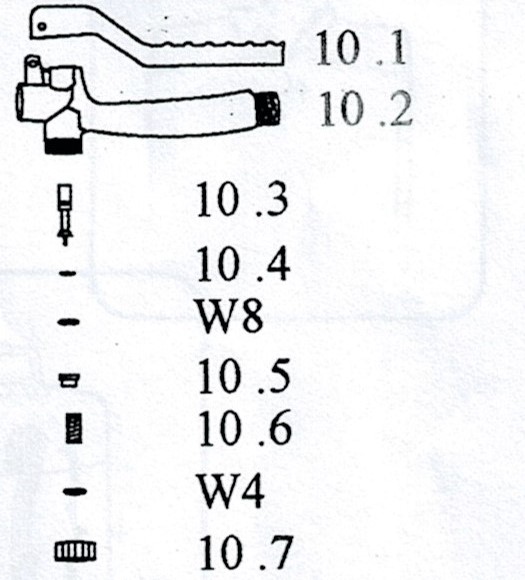

| 7) Dripping from the brass spindle (10.3) 8) Drpping from the nozzle tip without squeezing trigger(10.1 lever) | O-ring(10.4) Rubber disc(W8) | 1.O-Ring (10.4)is wom out-repalce a new 1.Rubber disc (W8)is wom out- Replace a new rubber disc (W8) O-Ring(10.4). |  |

| 9) Nozzle Jammed,cannot be adjusted anymore. | (OP.1)High performance spray nozzle. | 1.Avoid removing and tightening the nozzle cap by any tools. Use hand to hold the housing to remove and replace the cap or to adjust the spraying distance. |  |

It is very Important

Must clean the nozzle cap and filter(OP.3), properly after using the sprayer.

Problem & Remedies

General Use Conversion Table

1 Litre. = 1,000 c.c

= 0.22Gal

1 Gal. = 4.5Litres.

1kg/cm²= 14.19psi.

1kg. = 2.2Ibs.

1 in. = 2.54cm.

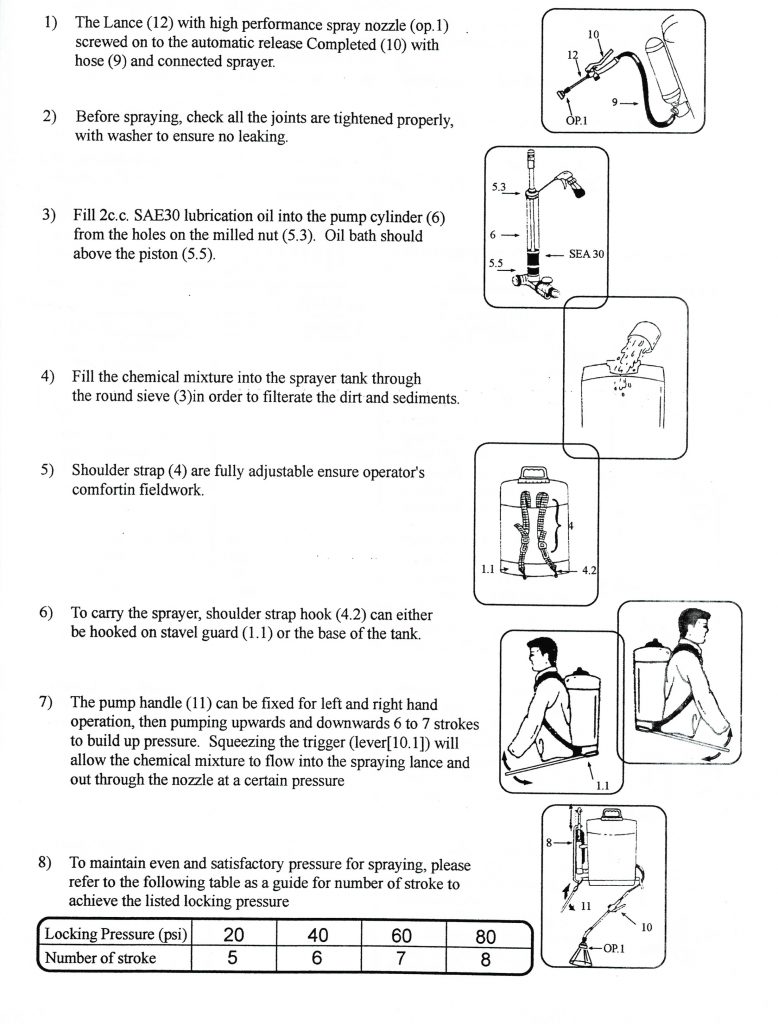

How To Assembly

Knapsack sprayer agricultural & other use